MEP Drafting

Services | Outsource MEP Drafting Services | MEP Drafting Services USA

MEP

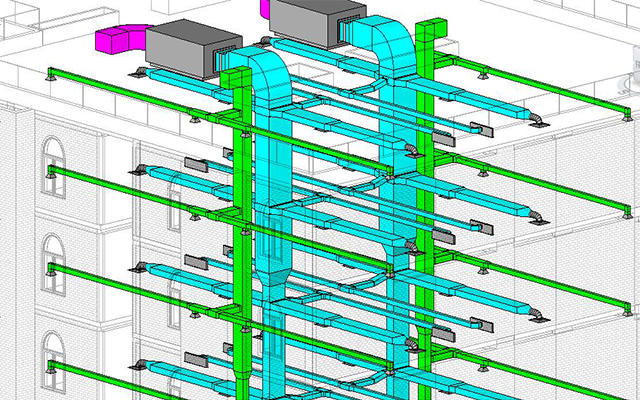

Drafting Services Mechanical, Electrical, and Plumbing Drafting Services is

the process of designing and drawing the mechanical, electrical, and plumbing

systems for a building or other structure MEP – Mechanical, Electrical, and

Plumbing Services Mechanical, Electrical, and Plumbing Drafting Services is the

process of designing and drawing the mechanical, electrical, and plumbing

systems for a building or other structure. This process includes developing

specifications for materials to be used in a project; preparing drawings to

show how these materials will be assembled; and estimating costs.

For MEP Design

Services there are three main steps: MEP Shop Drawing

Preparation, MEP BIM Coordination, and MEP Design Services. Drafting Services

is the process of designing and drawing the mechanical, electrical, and

plumbing systems for a building or other structure. MEP Shop Drawings

Preparation order to provide clear information about all of these systems

Preparing the shop drawings will involve drawing the mechanical and electrical

system schematics. Preparing the shop drawings will also require coordinating

with the project architect. The MEP engineer, who is responsible for drawing

all of the MEP systems, is also on site during this stage in.

This

process includes developing specifications for materials to be used in a

project; preparing drawings to show how these materials will be assembled; and

estimating costs. For MEP Design Services there are three main steps: MEP Shop

Drawing Preparation, MEP BIM Coordination and MEP Cost Estimating. MEP Shop

Drawing Preparation – This is the first step in the process which must be done

before any funds are granted to a project. It begins with drawings of the

layout of construction; this includes conceptual design, specifications, and

fabrication drawings. The client provides any requested information to their

architect or architect’s representative, who will then prepare a draft layout

drawing. The draft layout drawing will be sent to the engineer, who in turn

will prepare another draft layout drawing. The architect or engineer will then

send finished construction drawings to the Secretary of State for approval.

Siting – The site identification process can range from simple to more complex

depending on the complexity of the project. State Department Drawings.

The first step is to prepare shop drawings that include all the necessary information needed to manufacture parts or assemblies. The next step is to coordinate with Building Information Modeling (BIM) data including everything from schedules to quantities of material needed. Finally, it’s time for the design services which include developing specifications for materials to be used in a project; preparing drawings to show how these materials will be assembled; and estimating costs.

MEP drafting services process typically include the following steps:

1)

Specification Development – Defines the characteristics of a project and

specifies its parameters.

2)

Project Management / BIM Coordination – Gathers information on the project and

communicates with all parties. involved to ensure that the project will be

completed in a timely fashion.

3)

Design Services – Develops the plan for assembling building parts or assemblies

and communicates with those who need to know about them.

4)

Production Services – Coordinates with vendors and manufacturers to produce the

necessary materials for a project.

5)

Cost Estimation – Estimates costs of production, transportation, etc.

Our MEP Design and Drafting Services:

MEP BIM Services

MEP

BIM Coordination

MEP

Shop Drawings

MEP

3D Modeling

Mechanical

Room Modeling

Builders

Work Drawing

As-built

Drafting

Piping

Spool Drawing

MEP

Quantity Take Off

Dynamo

for Revit MEP

Mechanical

System

3D

Modeling

Reverse

Engineering

Electrical

schematics

Solar

panel detailing

CAD

Conversion

Electrical

System

Electrical

site plans

Electrical

one line diagrams (Riser diagrams)

Shop/

Fabrication drawings

Duct

layout drawings

Electrical,

power and lighting plans

Plumbing

System

Equipment

schedule

Natural

and LP gas piping drafting services

Compressed

air and medical gas system plan drawings

Demolition

and existing plan drawings

Drafting

services for domestic water plumbing

Shop

drawings, As-builts, specifications and coordination

Plumbing

and drainage drafting Services

Locate

and coordinate pipe sleeve requirements

Isometrics,

Riser diagrams, details, schematics and schedules

We provide MEP CAD Drafting Services for:

HVAC

Duct & Pipe

Plumbing

systems

Electrical

& fire systems

Mechanical

equipment & products

Machine

parts

Integrated

MEP systems

Our

MEP Drafting Services:

Construction

Drawings

Coordination

Drawings

Shop

Fabrication Drawings

Spool

Drawings

Penetration

Drawings

Isometric

Drawings

As-Built

Drawings

Erection

Layouts

Heating

and cooling systems layout

Fire

protection systems layout

HVAC

duct layout

HVAC

pipe layout

Electrical Drafting:

Electrical

riser diagrams

Lighting

circuits

Wiring

and cable drawing

Electrical

panel diagrams

Electrical

distribution layouts

Cable

tray layouts

Plumbing Drafting:

Domestic

water systems layout

Drainage

water piping layout

Natural

gas piping systems layout

MEP

Shop drawings

Water

distribution plans and diagrams

Piping

isometric drawings and sectional drawings

Request a free quote for your requirement of MEP

Engineering Services | MEP Drafting Services | MEP CAD Services | Shop/

Fabrication drawings | Plumbing and drainage drafting Services on info@mepglobalengg.com

Comments

Post a Comment